Your Cart is Empty

MOTO Products

shop your way

Choose a shopping experience

Same great Risk Racing products, 3 completly different ways to shop them.

Choose a shopping experience

Same great Risk Racing products, 3 completly different ways to shop them.

Lifestyle Shopping

eComm Shopping

Catalog Shopping

MOTO TYRES

MOTO Gear & Apparel

The Ultimate Moto Van Build

November 30, 2020 7 min read

Getting your bikes and gear to the track often seems to be an adventure in and of itself. Whether it be in the back of the pickup truck, box van, RV or toy hauler, we all have fond, and not so fond memories, of travels to our favorite riding destinations and motocross events. In the end, these vehicles are a means to help unlock our shared passion of riding dirt bikes and creating lasting memories and friendships.

On the other end of the spectrum, for those who have made motocross their career or business, a day at the track is like a day in the office. We’ve seen the factory teams with their massive double-stacker haulers in the pits at the Rockstar Nationals, but what we don’t see is all the logistics behind those rigs. Logistics is the blanket term to cover a laundry list of item such as trip permits, logbooks, maintenance, 18 tires all searching for the only piece of shrapnel on the highway and, of course, hours worth of setup and tear down each weekend. As impressive as these set-ups may be, they are certainly not practical for multiple mid-week track days to fine tune the latest weaponry in the factory race bike arsenal.

All this brings us to the folks at Huber Motorsports / Monster Kawasaki Pro Circuit who were in search of a solution that combines the amenities of their rig with the convenience and agility of something smaller for those all-important testing days. We can best describe it as the MotoVan equivalent of a factory race bike. No detail is overlooked, lots of trick parts and an off-the-charts ‘wow’ factor.

It’s no secret, Gerhart and Christian Huber, owners of Huber Motorsports like to make a splash both on and off the track. Their presence on the track and at pitside never goes unnoticed and they sought out a company to turn their 2019 Mercedes Sprinter into the ultimate MotoVan. To make it happen, they tapped another familiar face in the Canadian motocross race pits, Matt Bannon, member of the rival Honda Canada Fox GDR race team and owner of Bristol Coachworks in Ingersoll, Ontario.

Bannon along with his business partner, Errol Thorpe, formed Bristol in 2017 and began designing and manufacturing their own line of luxury small buses and custom Ford Transit vans. They have formed a talented team of individuals who turn out some unbelievably impressive custom vehicles and projects right here in Canada. The completed Huber Motorsports MotoVan made its first appearance in the pits at San Del Lee this August. After a brief chat and tour from Bannon, the MXP crew decided to head to Ingersoll this off-season to see the van in more detail and find out just what goes on behind the scenes to bring a project like this to reality.

Upon arriving at Bristol Coachworks, one thing is very apparent: this is not your average shop. Its stark white walls and epoxy floor are more akin to a medical facility than a manufacturing shop. If the team at Bristol set out to make a strong first impression for those who walk through their doors, mission accomplished. Timing for the MXP crew was perfect as the Huber Motovan was back to the shop for some final offseason touches and an added bonus were the number 2 and 19 bikes of Goerke and Weltin that accompanied it (admiring these factory race bikes in all their glory never gets old).

After a brief tour of the facility and meeting with team members, we sat down with Matt Bannon to pick his brain and get a better understanding of how this project came to be. “Gerhart, Christian and I began chatting about this project back in July of 2019 after the Gopher national and planning really started taking shape in October,” Bannon said. Although the team at Bristol had never built a motocross inspired vehicle, Matt said his passion for all motorsports and his familiarity with the requirements this van may need from his time spent under the GDR tent helped the planning phase dramatically. The long and short of it was this: Huber Motorsports wanted something significantly more convenient and agile to use day in and day out than their rig yet required the amenities and tooling for some serious testing days.

“I used my own knowledge and experience, had a major brainstorm session with Christian and also leaned on the likes of Derek Schuster and Justin Petker to run ideas past them and a bunch of ‘what do you think of this?’ type conversations,” he added.

One thing became clear very during the planning phase Bannon said, this project vehicle had to make a statement. Beyond all the amenities needed for a day of testing at the track, the overall package needed to command attention and be a marketing piece for the team. This was music to the team at Bristol’s ears as their attention to detail and creativity is what really sets their creations apart.

“To be honest, this was a bit of a dream project,” said Bannon. “We had a real good understanding of the ‘musthaves’ from Gerhart and Christian, and they brought up some cool ideas like solar power and from there I knew this was not going to be your average MotoVan project. They wanted this to be innovative, they wanted it to command attention,” Bannon added.

During our conversation at Bristol, we discovered no matter how simple or complicated a project is, they essentially all start out the same. “The foundation for any build is a solid plan, bill of material and electrical schedule,” said Andrew Landick, Bristol Shop Manager. “This particular project is by no means a do-it-yourself home build, but the fundamentals are all the same even if you are tackling something yourself in your driveway or home garage. High quality sound deadening material, insulation and a wiring plan. It may not be the most glorious stage, but it sets the project off on the right foot,” he added.

As our MXP crew crawled around, inside, under and on top of the Huber Sprinter, we were blown away by how Bristol seamlessly integrated so many features into such a small space. We’re talking 10-gallon air compressor, exterior and interior air fittings, 1500- psi electric pressure washer , 3000-watt inverter charger, air-ride suspension, a massive stereo, tool chests, tire carrier, 150 litres of water, suspension sink and waste oil reservoir and suspension locker, just to name a few.

“We’ve become masters of spatial planning and integration,” Bannon said. “The issue is vehicles seldomly cooperate. The perfect spot we initially planned for the pressure washer in proved to be impossible when it came down to it.” “All of a sudden this has to be relocated and it throws the whole plan out of sync and it’s back to the drawing board,” Bonner said. “If you are planning a build at home, painter’s tape is your best friend, lay out your vision on the floor and walls of your van but get underneath and make sure nothing important is in the way. You don’t want any drill bits through a gas tank or wiring harness” he added.

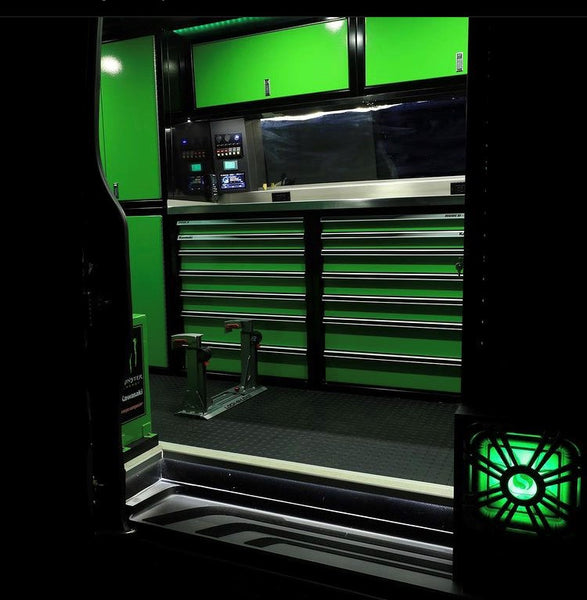

One of the biggest showstoppers of this build greets you the moment the sliding door opens and comes in the form of a Kawasaki green suspension cabinet with clear plexiglass front. If there is ever an appropriate time to use the phrase ‘suspension porn’, this is it. Two sets of unobtanium Pro Circuit front forks are on display and accented with coloured LED backlighting and polished stainless-steel mirror. We then experience sensory overload like a kid on Christmas morning as we are greeted by a one-off custom stainless work top with integrated suspension sink, powder coated tool chests, cabinets and some ultra-trick water tanks to feed the on-board pressure washer.

Bannon said one of the features he is most proud of are the custom aluminum water tanks which feed the integrated pressure washer. “One of our main goals in this shop is combining aesthetics, wow-factor and real-world practicality in our projects. In this case, the water tanks serve multiple purposes. They offset the abundance of weight on the driver side, act as a storage system for the Matrix Concepts fuel jugs and also as a spot for the riders to sit on while they get their gear on and, in my opinion, provide some serious wow factor,” Bonner said.

As we were wrapping up our visit, there was still one major item everyone was wondering about but had gone unmentioned and we weren’t leaving the shop until we got some details. Sitting on the roof of the van was a custom roof-rack, side awning, three flush-mount solar panels and enough LED light bars to make the average baseball stadium jealous. “The 300-watt solar panels are accompanied by a battery bank of four rear lithium batteries in a custom mount which help the van survive the electrical demands placed on it during a long day at the track. As a back-up there is a shore-power connection, but the goal was for it to survive off-grid as long as possible,” Bonner explained.

After our in-depth tour of this MotoVan, the consensus from the MXP crew is a genuine appreciation for the craftsmanship and attention to detail we see at every turn. Subtle details and striping on the tool cabinets and wheels provided by Lime Nine and seat-covers highlighted by Kawasaki green accents and the Huber Motorsports logo stand out. It’s no different than looking at a factory race bike. There is serious initial ‘wow’ factor but as you spend more time admiring it the real detail and hard work becomes apparent.

Like our racers on the podium, Bannon has a lot of people to thank for making this project possible. “First and foremost, Gerhart, Christian, Chad and the entire team thank you for putting your trust in us. Newf at Matrix Concepts, Brad and the folks over at Easy-Kleen, Brendan at Lime Nine, John at Moduline, Trevor at Risk Racing, Mark at Surf & Turf, Mike at Henderson’s Powdercoating, John at Cook Sheet Metal, Sean at Thule Canada, and Logan and Brett at GeeVee Race. Beyond that, thank you to our team here at Bristol that put in a ton of time making this happen, we truly have an incredible group of people here,” Bannon said.

Check out this short video detailing the moto van build here:

Bristol Coachworks / Macnab Transit

439 Bell St. Ingersoll, ON

519-485-4287 info@macnabtransit.com

MOTOVAN STATS

Bike Capacity: ................................................. 2

Stereo System: ... XXX Watts*need to figure out

Solar Panels: ...................................... 300 watts

Battery Bank Capacity: .............. 420 amp-hours

Water Capacity: .................................. 153 litres

Waste Suspension Oil Capacity: ......... 5000 mL

LED Light Bars: .................................. 852 watts

Pressure Washer: ................... 1,500 psi electric

Air Compressor: ................................ 10 gallons

Tire Carrying Capacity: ............... 4 front / 4 rear

Leave a comment

Comments will be approved before showing up.

Subscribe

Sign up to get the latest on sales, new releases and more …

Limited Time 10% Off

Save on your 1st order and get email offers when you join.

Eligible for first-time website purchases only. Emails may take a few minutes to process and could get flagged by email providers as junk so be sure to wait a little bit and check your junk and/or spam folders.

UK/EU▾

UK/EU▾